Understanding Active Harmonic Filters and Their Role in Power Quality

What Are Active Harmonic Filters (AHFs)?

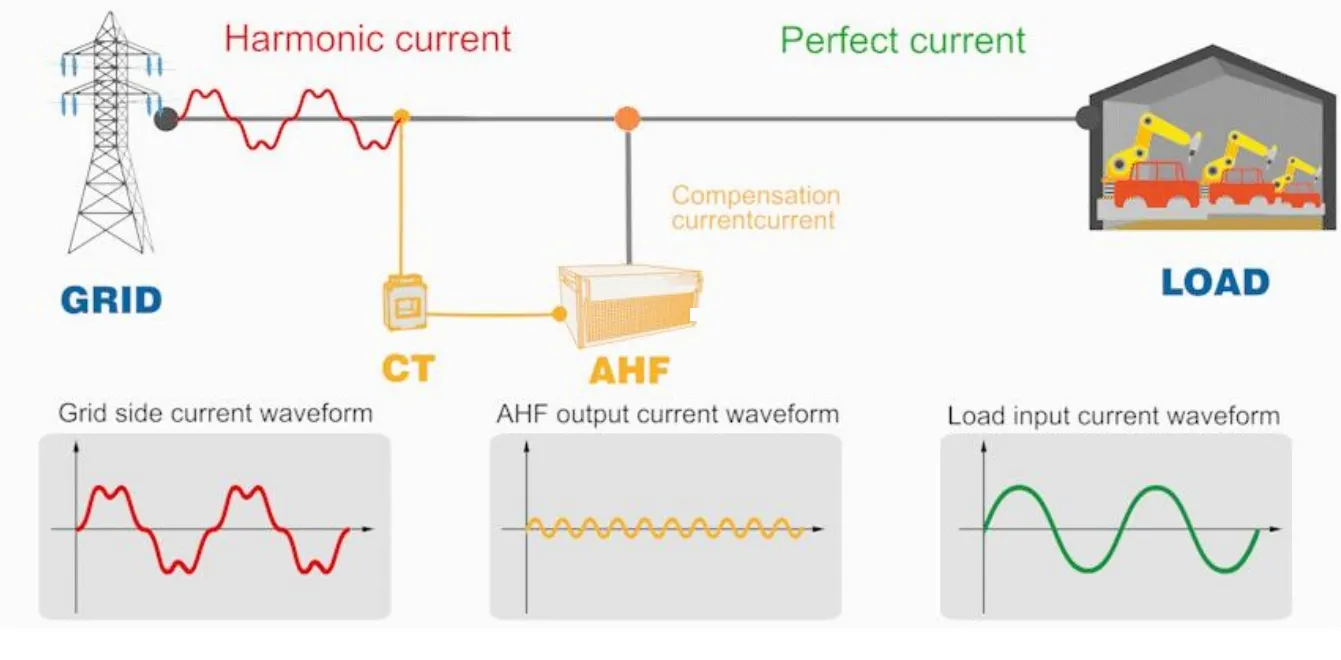

Active Harmonic Filters or AHFs represent a significant advancement in power electronics, specifically created to tackle those pesky harmonic distortions that plague electrical systems. These differ from traditional passive filters which work at fixed frequencies. Instead, AHFs constantly monitor current waveforms as they happen and then send out opposing signals to neutralize the harmonics. What makes this tech stand out is its ability to handle frequencies all the way up to the 50th order. For facilities running modern equipment like variable speed drives, uninterruptible power supplies (UPS), and various nonlinear loads, AHFs offer real world benefits that just aren't possible with older filtering methods.

The Impact of Voltage and Current Harmonics on Power Systems

Harmonic distortions degrade power quality by:

- Overheating transformers and motors (reducing lifespan by 30–40% in severe cases)

- Triggering nuisance tripping of circuit breakers

- Increasing energy losses by 8–15% in distribution systems (Ponemon 2023 study)

Unmanaged voltage harmonics above 5% THD (Total Harmonic Distortion) can cause voltage flattening, leading to equipment malfunctions in sensitive medical imaging systems and semiconductor manufacturing tools.

How Active Power Filters Improve Power Quality

Modern AHFs achieve THD reduction below 5% even in systems with 25–30% initial distortion. Key improvements include:

| Metric | Before AHF | After AHF |

|---|---|---|

| Current THD | 28% | 3.8% |

| Power Factor | 0.76 | 0.98 |

| Transformer Losses | 14.2 kW | 9.1 kW |

This real-time correction prevents resonance issues common in capacitor-based solutions while compensating for both harmonics and reactive power. The 2024 Power Quality Report shows facilities using AHFs experience 23% fewer unplanned downtime events compared to passive filter installations.

Why THD Control Is Critical for Nonlinear Loads

Equipment such as variable frequency drives (VFDs) and rectifiers are known for creating harmonic distortions that mess with power quality and can actually increase equipment losses by around 15%, according to recent research from Journal of Power Sources in 2025. When Total Harmonic Distortion (THD) goes above 8% in either voltage or current, problems start happening. Transformers get overheated, protective relays might trip unexpectedly, and all sorts of sensitive gear gets disrupted. Facilities that run lots of motors need to keep their THD levels under 5% if they want to stay within IEEE-519 guidelines. Not doing so could lead to fines and operational headaches down the road. Many plants have learned this the hard way when unexpected failures hit during peak production times.

Response Time and System Stability in Active Filter Performance

The latest generation of active harmonic filters (AHFs) can respond in less than 5 milliseconds, which means they correct those pesky load fluctuations as they happen. Such quick reactions are really important for preventing those annoying resonance problems that pop up in capacitor banks, plus they cut down on voltage sags that can mess up operations. According to research published in 2025 looking at how grids stay stable, AHFs equipped with smart control systems actually speed up convergence by around 38% when compared to older passive methods. What this means practically is that these systems keep running smoothly even when there's a sudden jump or drop in load of about 30%.

Case Study: Reducing THD from 28% to Under 5% with an Advanced AHF

A factory running 12 megawatts worth of CNC machines saw their total harmonic distortion drop dramatically from 28% down to just 3.27% once they installed a modular active harmonic filter system. These filters tackled those pesky 7th and 11th order harmonics coming through the 480 volt bus ducts, which also cut daily transformer losses by around 9.2 kilowatt hours. Energy audits done after installation showed the investment paid for itself within about 16 months thanks to less equipment downtime and no more dealing with maintenance issues caused by electrical harmonics messing up the system.

Balancing High-Speed Response with Grid Stability

Overly aggressive harmonic correction can destabilize weak grids or interact with legacy protection systems. Leading AHFs now incorporate impedance-scaling algorithms that adjust compensation rates based on real-time grid strength measurements, achieving harmonic mitigation without exceeding EN 50160 voltage fluctuation limits.

Active Filter vs. Passive Filters and Capacitor Banks: A Comparative Analysis

Limitations of Passive Filters in Modern, Dynamic Load Environments

Passive filters struggle to adapt to rapidly changing industrial loads due to their fixed-tuned design. While cost-effective for predictable harmonic frequencies (like 5th or 7th harmonics), they risk system resonance when external harmonics interact with their LC circuits. A 2023 study found passive filters caused power factor issues in 42% of retrofitted facilities with variable frequency drives (VFDs) and renewable energy sources. Their inability to address interharmonics—common in modern power systems—limits effectiveness in facilities requiring below 8% THD compliance.

Advantages of Shunt Active Power Filters in Reactive Power and Harmonic Compensation

Active filters outperform passive solutions through real-time harmonic current injection and dynamic reactive power compensation. Unlike capacitor banks (which only address displacement power factor), active filters simultaneously mitigate harmonics and improve true power factor.

| Feature | Active Filter | Passive Filter | Capacitor Bank |

|---|---|---|---|

| Response Speed | <1 ms | 10–100 ms | N/A |

| Harmonic Range | 2nd–50th order | Fixed frequencies | No compensation |

| Scalability | Modular expansion | Fixed design | Limited staging |

The 2024 Power Quality Report shows active filters reduced energy losses by 18% compared to passive solutions in manufacturing plants with nonlinear loads.

When to Use Hybrid Solutions: Combining Active Filter with Capacitor Banks

Hybrid configurations prove cost-effective when addressing both harmonic distortion (>15% THD) and large reactive power demands (>500 kVAR). Active filters handle high-frequency harmonics, while capacitor banks manage fundamental frequency reactive power—a combination achieving 97% system efficiency in steel mills according to 2023 field data. This approach reduces active filter sizing by 40–60% compared to standalone installations, particularly valuable in brownfield sites with space constraints.

Design and Integration Considerations for Active Filter Deployment

Modular Design Benefits for Scalability and Maintenance

Power systems can now handle changing harmonic issues thanks to modular active filter designs, all while keeping operations running smoothly. Facilities love these setups because they can simply add standard units as needed when expansion comes along. Research indicates that going modular cuts down on maintenance stoppages somewhere between 40% and 60%, which beats out traditional fixed setups hands down. Industries really benefit from this flexibility since their energy demands constantly shift with new machinery installations or when production scales up. Think about manufacturing plants during busy seasons or when they bring in newer, more efficient equipment.

Mechanical and Electrical Integration Challenges in Retrofit Applications

When adding active filters to older power distribution systems, engineers need to look closely at space limitations and whether the system can handle the new equipment. Research from 2022 on longer distribution feeders pointed out several major issues that come up during these retrofits. First, managing heat becomes tricky when there's not enough room in crowded electrical cabinets. Second, many old systems run on different voltage levels than what modern filters need. And third, getting the new filters to work properly with the existing protective relays is another common headache. Most successful projects end up needing special mounting brackets and sometimes even fancy transformers to connect everything together without causing problems down the line.

Customizing Active Filter Solutions (AHF, SVG, ALB) to Match Load Profiles

Getting rid of harmonics works best when we match the right filter tech to what's actually happening in the system. Shunt active power filters, or AHFs as they're called, really shine at cleaning up those pesky current harmonics coming from variable speed drives. Meanwhile SVGs tend to do better job stabilizing voltage fluctuations in places like solar farms. For tricky situations where industrial loads keep changing, many engineers turn to hybrid setups mixing active filters with passive parts. Some studies have shown these mixed systems cut down on harmonic issues by around 35 or so percent compared to just using one type alone. And there's another angle too adaptive control algorithms that tweak filtering settings on the fly based on what sensors pick up from the load itself. This kind of smart adjustment makes a big difference in day to day operations across different facilities.

Applications and Industry-Specific Requirements for Active Filter Systems

Active Filter in Manufacturing: Mitigating Harmonics from VFDs and Rectifiers

Manufacturing plants today struggle with power quality issues mainly because of those variable frequency drives (VFDs) and rectifiers running around. These devices create all sorts of harmonics that mess up the voltage waveform patterns. What happens next? Well, transformers start getting too hot, motors tend to fail prematurely, and companies get hit with fines when their total harmonic distortion (THD) goes beyond acceptable levels. To fix this mess, many facilities install active filters these days. They work by putting out counter currents that basically cancel out the problematic 5th, 7th, and 11th order harmonics. This brings THD down below 5%, which is pretty good considering how bad things can get in factories with lots of CNC machines and welding gear constantly running.

Static Var Generators (SVG) in Renewable Energy and Grid Support

With the rapid expansion of solar farms and wind turbines across the country, Static Var Generators (SVGs) have become essential for keeping electrical grids stable when power output fluctuates. These advanced systems differ from old school capacitor banks because they can adjust reactive power almost instantly, which helps maintain steady voltage even when clouds pass over solar panels or winds die down at turbine sites. Research published last year found that SVG installations boosted how well renewable energy facilities handle grid faults by around 40 percent. This improvement means fewer instances where operators have to shut down production temporarily due to voltage drops, ultimately saving money and preserving energy supply reliability.

Ensuring Power Reliability in Data Centers and Hospitals

Voltage problems caused by harmonics can really mess things up in places where reliability matters most, such as hospitals and data centers. These issues often lead to expensive downtime or damaged equipment. Active filters help cut down these risks by keeping total harmonic distortion under control, ideally below 3%. That's what the IEEE 519-2022 guideline suggests for protecting sensitive equipment like medical imaging devices and computer servers. Take one particular Tier IV data center for instance. After they installed a modular active filtering system, they saw something remarkable happen. The number of times breakers tripped due to harmonics dropped dramatically, around 90% according to their records. Not bad at all when considering how much money those trips used to cost them.

Growing Demand for Active Filter in EV Charging Infrastructure

The rise of electric vehicles has created a big need for active filters because those powerful DC fast chargers pump all sorts of unwanted electrical noise (around 150 to 300 Hz) right back into the power grid. Most major companies in the space have started building these filters right into their charging stations themselves. They need to comply with those strict IEC 61000-3-6 regulations, plus handle loads ranging from 150 up to 350 kilowatts. We're seeing something interesting happen too - many installations are mixing active filters with traditional passive reactors. This combo approach seems to strike just the right balance between what it costs and how well it works, especially important when setting up those dense urban charging networks where space is tight and money matters.

FAQ

What are active harmonic filters and how do they work?

Active harmonic filters (AHFs) are advanced power electronics designed to neutralize harmonic distortions in electrical systems by continuously monitoring current waveforms and sending out opposing signals.

Why are voltage and current harmonics problematic?

Harmonics degrade power quality by causing overheating in transformers, tripping circuit breakers, and increasing energy losses. They can also lead to equipment malfunctions when unchecked.

How do AHFs improve power quality?

AHFs reduce total harmonic distortion (THD) to below 5%, prevent resonance issues, and compensate for both harmonics and reactive power, resulting in fewer downtime events.

What's the difference between active and passive filters?

Active filters provide real-time harmonic mitigation and reactive power compensation, while passive filters are fixed-tuned and struggle with changing loads, making them less effective for modern systems.

Where are active filters used?

Active filters are widely used in industries like manufacturing, renewable energy, data centers, hospitals, and EV charging infrastructure to maintain power quality and reliability.

Table of Contents

- Understanding Active Harmonic Filters and Their Role in Power Quality

- Why THD Control Is Critical for Nonlinear Loads

- Response Time and System Stability in Active Filter Performance

- Case Study: Reducing THD from 28% to Under 5% with an Advanced AHF

- Balancing High-Speed Response with Grid Stability

- Active Filter vs. Passive Filters and Capacitor Banks: A Comparative Analysis

- Design and Integration Considerations for Active Filter Deployment

- Applications and Industry-Specific Requirements for Active Filter Systems

- FAQ