Understanding Harmonics and Their Impact on Industrial Power Systems

Harmonics – high-frequency distortions in electrical waveforms – are a critical challenge for industrial power systems. These disturbances, occurring at integer multiples of the fundamental frequency (e.g., 3rd, 5th, 7th harmonics), degrade voltage and current quality, leading to inefficiencies and equipment damage.

What Are Harmonics and How Do They Affect Power Quality?

When equipment like variable frequency drives (VFDs) or those switched-mode power supplies get involved, they mess with the normal sine wave pattern of electricity flowing through circuits. What happens next is pretty interesting - this kind of electrical disturbance generates what engineers call waveform noise that spreads throughout the entire system. For buildings where harmonic levels go above 5%, there's actually about a 12 to 18 percent jump in wasted energy from all that extra reactive power bouncing around. According to research published last year on harmonic effects, these unwanted frequencies blend right into the main electrical signals, messing up both the voltage and current patterns across the whole installation.

Common Sources of Harmonic Distortion in Automated Industries

-

Motor drives: VFDs in conveyor systems or HVAC units inject harmonics during speed modulation.

-

LED lighting: High-efficiency lighting generates 3rd-order harmonics that overload neutral conductors.

-

Uninterruptible power supplies (UPS): Modern UPS systems introduce harmonics during battery charging cycles.

A 2023 audit of 12 automotive plants revealed facilities using these technologies had 2–3× higher harmonic levels than those dominated by passive loads.

Impact of Non-Linear Loads on Voltage and Current Waveforms

Non-linear equipment forces current to flow in abrupt pulses rather than smooth sine waves, resulting in:

-

Voltage flattening: Peaks in 480V systems may drop to 450V under harmonic stress.

-

Eddy current losses: Transformers experience up to 20% more core heating at 15% total harmonic distortion (THD).

-

Resonance risks: Capacitor banks interacting with harmonics can amplify distortion to unsafe levels.

These effects accelerate insulation degradation and trigger nuisance tripping of protective relays. According to a 2024 IEEE report, facilities neglecting harmonic mitigation face 34% higher maintenance costs over five years compared to those using active filtering solutions.

This systemic vulnerability underscores why industrial operators increasingly adopt active harmonic mitigators to stabilize power quality dynamically.

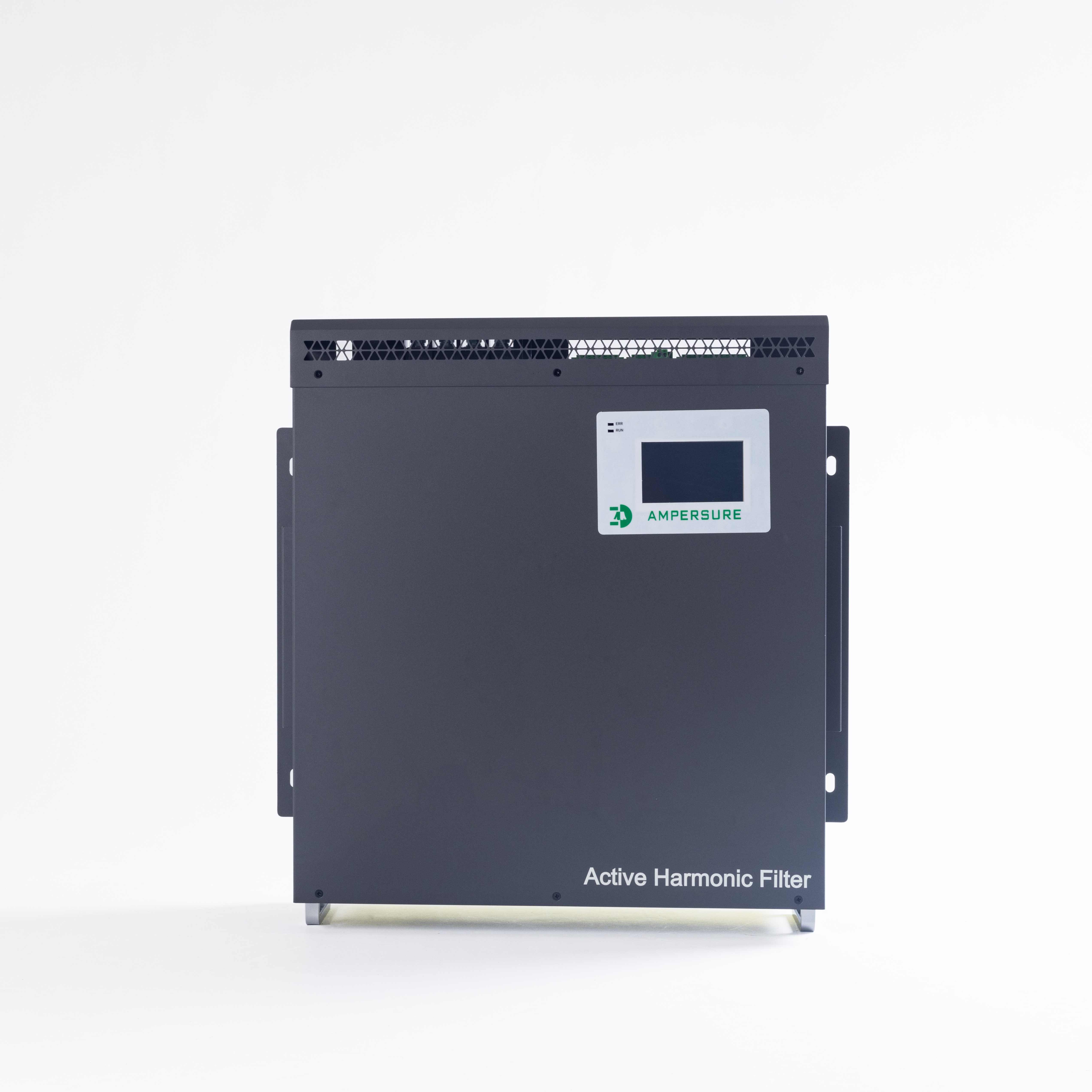

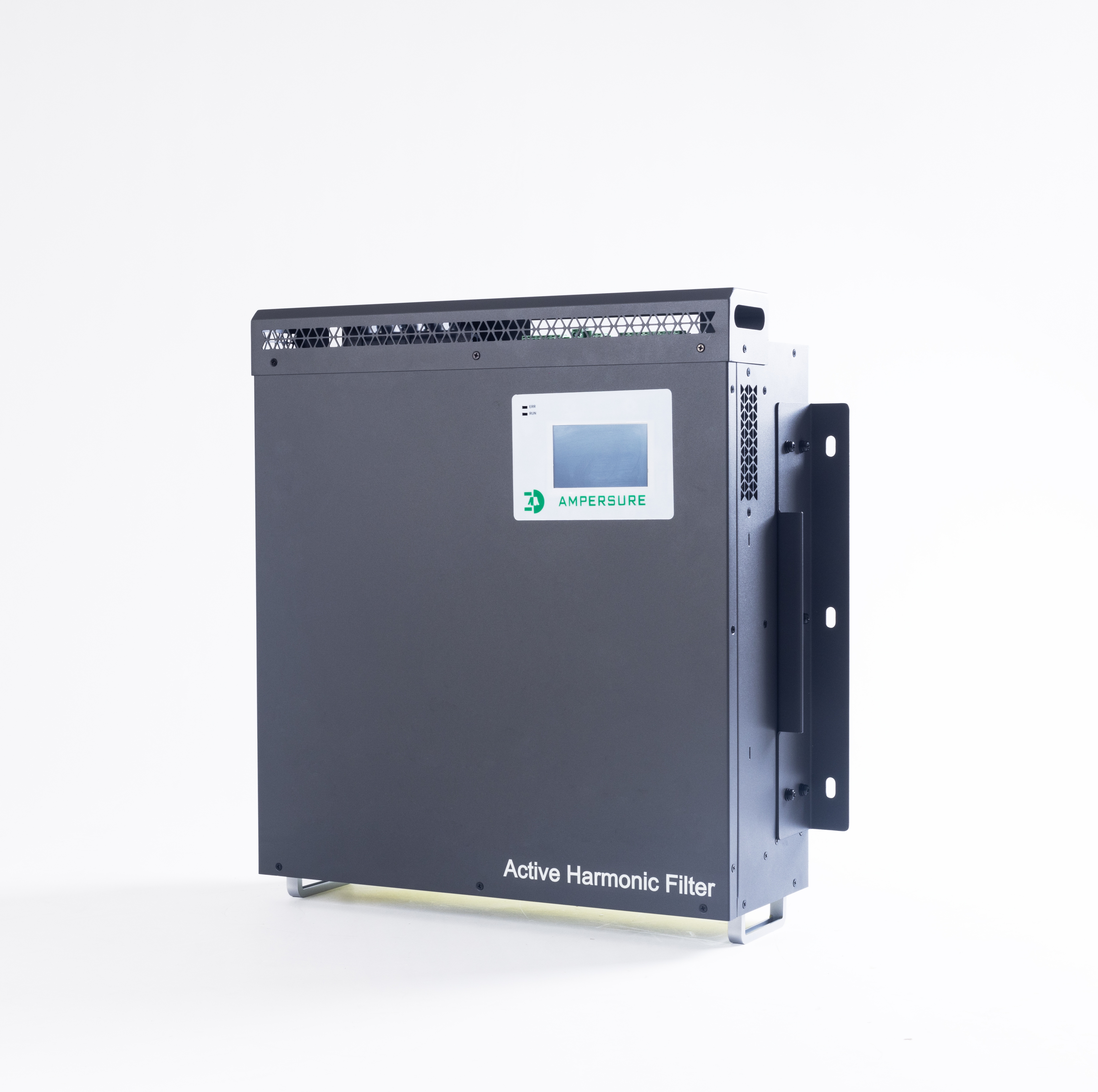

How Active Harmonic Mitigator Works to Stabilize Power Supply

Active Harmonic Filter Operation and Effectiveness Explained

Harmonic mitigation devices keep track of voltage and current waveforms through digital signal processing technology. These systems work by detecting those pesky harmonic distortions caused by nonlinear loads in the system. Once identified, they send out corrective currents that match in strength but oppose in direction, which basically cancels out the unwanted harmonics. Take a standard 480 volt industrial setup for example. Before installation, THD levels might sit around 25%. After putting these mitigators into play, most facilities see those numbers drop down under 5%, right where they need to be according to the latest IEEE 519 guidelines from 2022.

Real-Time Monitoring and Dynamic Harmonic Compensation Techniques

Modern systems use adaptive algorithms to track harmonic frequencies in real time, adjusting compensation within milliseconds to respond to load fluctuations. This dynamic capability surpasses passive filters, which cannot adapt to variable harmonic profiles. Key features include:

-

Adaptive Bandwidth Tuning: Automatically prioritizes dominant harmonics (e.g., 5th, 7th, 11th) based on system demands.

-

Multi-Layer Protection: Safeguards against overvoltage and thermal stress during transient surges.

Control Strategies for Active Filtering and Harmonic Suppression

Advanced control logic enables selective suppression of targeted harmonics while minimizing energy loss. Phase-locked loop (PLL) synchronization ensures accurate waveform alignment, even under unbalanced grid conditions. In multi-unit installations, coordinated control systems share harmonic data across devices, optimizing performance in large-scale industrial networks.

Comparing Filter Technologies: Why Active Harmonic Mitigator Outperforms Passive Solutions

Key Differences Between Passive and Active Harmonic Filters

Passive harmonic filters rely on fixed inductor-capacitor (LC) circuits tuned to specific frequencies, limiting their effectiveness to stable, predictable loads. In contrast, active harmonic mitigators use power electronics and real-time algorithms to detect and counteract harmonic distortion across a broad spectrum.

| Criteria |

Passive Filters |

Active Harmonic Mitigators |

| Response Time |

Static (millisecond-level delay) |

Dynamic (microsecond-level correction) |

| Adaptability |

Limited to pre-defined harmonic profiles |

Adjusts to fluctuating load conditions |

| Installation Flexibility |

Requires precise impedance matching |

Compatible with diverse system layouts |

Limitations of Passive Filters in Dynamic Industrial Environments

Passive filters struggle in environments with variable-frequency drives (VFDs) and servo systems, where harmonic content changes frequently. Their fixed tuning can lead to:

-

Resonance risks with grid impedance, amplifying certain frequencies.

-

Overcompensation in lightly loaded scenarios, creating leading power factors that strain equipment.

-

40% lower effectiveness in systems with variable non-linear loads compared to active solutions.

Advantages of Active Harmonic Mitigator in Responsiveness and Precision

Active mitigators excel in dynamic settings by continuously monitoring waveforms and injecting inverse-phase harmonics. Benefits include:

-

THD reduction to <5% under rapid load changes, exceeding IEEE 519-2022 requirements.

-

Simultaneous power factor correction, avoiding utility penalties for reactive power.

-

Precision targeting of 2nd to 50th order harmonics–far beyond the capabilities of passive LC filters.

For instance, real-world implementations show active filters achieving 92% harmonic suppression in automotive manufacturing plants with minimal maintenance needs.

Measuring and Achieving Optimal THD Reduction with Active Harmonic Mitigator

Measuring THD: Benchmarks for Power Quality Compliance

According to IEEE 519 standards, industrial facilities need to keep their Total Harmonic Distortion under certain limits - around 5% for voltage (THDv) and about 8% for current (TDD). When these numbers go overboard, things start going wrong pretty fast. Equipment tends to overheat, capacitors might blow out, and plants can lose anywhere from 10 to 15 percent of their energy if they don't have proper compensation systems in place. That's where active harmonic mitigators come into play. These devices constantly monitor what's happening in the system, catching those pesky transient harmonics that regular measurements just miss. They basically act as real time watchdogs for electrical quality issues that would otherwise slip through the cracks during standard inspections.

Quantifying THD Reduction Using Shunt Active Filters

Active harmonic mitigators connected in shunt configuration can cut total harmonic distortion (THD) down between 75 to 90 percent in systems dealing with non linear loads according to research published last year looking at semiconductor manufacturing facilities. These devices kick into action just 2 milliseconds after sensing any distortion problems, way quicker than traditional passive filters that usually take somewhere between 100 and 500 milliseconds to react. The speed difference really matters when it comes to keeping power quality consistent across industrial settings where robots are assembling components or where programmable logic controllers manage critical equipment operations throughout the day.

Case Study: Active Harmonic Mitigator Implementation in a Manufacturing Plant

A Tier-1 automotive plant reduced harmonic-related downtime by 82% after installing an active harmonic mitigator:

| Parameter |

Pre-Installation |

Post-Installation |

Compliance Standard |

| Voltage THD (THDv) |

7.2% |

3.8% |

IEEE-519 ±5% |

| Current TDD |

12.1% |

4.9% |

IEEE-519 ±8% |

| Energy Losses |

14% |

6.2% |

– |

The system’s adaptive filtering algorithms neutralized harmonics from over 120 VFDs while maintaining a 0.98 power factor across all production shifts. Annual maintenance costs dropped by 37% due to reduced transformer stress and eliminated capacitor failures.

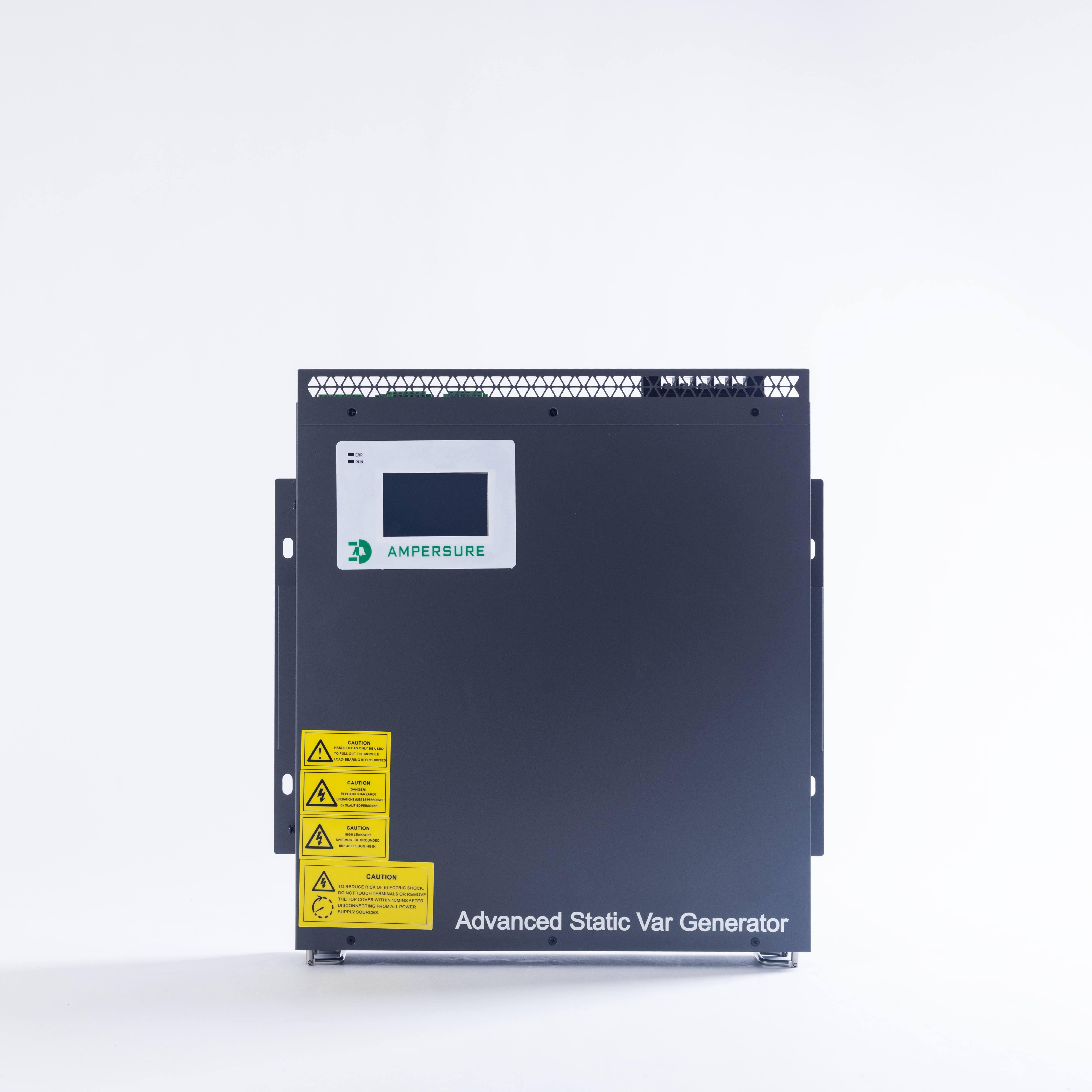

Integrating Active Harmonic Mitigator in Modern Industrial Power Infrastructure

Hybrid Active Filter Design for High-Power Industrial Applications

Hybrid active filters mix traditional passive components with modern harmonic mitigation tech to tackle a wide range of frequencies. These systems work great in big power applications over 2 megawatts like those found in semiconductor manufacturing facilities. They bring down voltage total harmonic distortion to below 3%, which is way better than the IEEE 519-2022 standard that allows up to 5%. The passive parts handle those lower order harmonics, whereas the active components kick in to control those pesky higher frequencies all the way up to the 50th order. This setup helps protect delicate CNC machines and other automation gear from electrical disturbances that could cause problems on the factory floor.

Integration with Existing Power Systems and Scalability

Today's active harmonic mitigators come with modular designs that make them much easier to install in older systems. These units plug into existing electrical panels alongside current equipment through common standards such as IEC 61850. This setup allows for scaling from small fixes on individual machines all the way up to comprehensive control across entire facilities. According to a recent industry report from 2023, companies saved around 34 percent on installation expenses when they opted for these modular solutions instead of completely replacing their infrastructure. What's more impressive is that these devices managed to cut down harmonic distortion by nearly 91 percent even in facilities where different types of loads were running simultaneously.

Ensuring Long-Term Equipment Performance and System Stability

Advanced mitigators use continuous impedance matching to prevent resonance when new equipment is added. Predictive analytics track capacitor degradation and transformer thermal profiles, extending asset lifespans by 7–12 years in energy-intensive operations. Facilities using these systems report 28% fewer unplanned outages annually through real-time monitoring of waveform purity.

FAQ Section

What are harmonics in industrial power systems?

Harmonics are distortions in electrical waveforms occurring at integer multiples of the fundamental frequency, which can degrade power quality and lead to inefficiencies and equipment damage in industrial systems.

Why do industrial facilities use active harmonic mitigators?

Industrial facilities use active harmonic mitigators to stabilize power quality dynamically, reduce maintenance costs, and prevent equipment damage caused by harmonic distortions.

How do active harmonic mitigators differ from passive filters?

Active harmonic mitigators use real-time algorithms to dynamically counteract harmonic distortion, providing faster response and adaptability compared to static, fixed-frequency passive filters.

What industries benefit most from harmonic mitigation?

Industries with significant non-linear loads, such as automotive, semiconductor manufacturing, and facilities with automation equipment, benefit greatly from harmonic mitigation.

Hot News

Hot News