Understanding Harmonic Distortion and System Requirements

Getting harmonic distortion under control in electrical systems matters a lot when it comes to keeping things running smoothly and making sure equipment lasts longer. When we look at an electrical setup through a full audit, it helps spot those pesky current and voltage distortions that basically tell us what kind of harmonic issues our system has. Good old fashioned tools like power quality analyzers come in handy here since they let us get accurate measurements of all these variables. What we find during testing shows which frequency ranges have too much harmonic activity, giving us clues about how bad they're affecting performance and wearing down equipment over time. Looking back at past operation records also tells stories about harmonic problems developing over months or years, which points us toward real solutions instead of just temporary fixes.

Assessing your electrical system's harmonic profile

Assessing the harmonic profile of an electrical system requires a comprehensive audit measuring both current and voltage distortions across different points in the network. Power quality analyzers provide precise measurements that create detailed maps of harmonic activity within the system. These instruments capture waveform characteristics at various frequencies, helping identify problem areas where harmonic distortion becomes significant enough to warrant attention. Understanding the effects of these harmonics on overall system performance and equipment longevity remains critical for maintenance planning. Looking at historical records of operational parameters and load demands offers valuable perspective on how harmonic distortion patterns evolve over time, making it possible to anticipate potential problems before they become serious issues affecting production or safety.

Identifying critical non-linear loads generating harmonics

Finding where harmonics come from remains an important part of the troubleshooting process. Things like variable frequency drives (VFDs), rectifiers, and those UPS systems tend to be major culprits when it comes to harmonic generation. When looking at these different components, engineers need to figure out exactly how much each one contributes to the overall harmonic content in the system. The usual approach here is some sort of harmonic current spectrum analysis which basically tells us what kind of problems each component might cause. Looking at load profiles gives additional information about not just how bad the harmonics are now, but also what could happen over time if nothing changes. Once all this data is collected and understood, technicians can then develop proper mitigation techniques that actually make a difference in keeping electrical systems running smoothly without unnecessary downtime.

Determining compliance needs with IEEE 519 standards

Sticking to IEEE 519 standards matters a lot when it comes to keeping voltage distortion at acceptable levels across facilities. These standards actually define what counts as too much distortion for both voltage and current in places like factories and office buildings. When our team looks at how well a system meets these requirements, we can spot where things might be going wrong. Fixing those issues isn't just good practice either – companies that ignore these rules often face hefty fines down the road. We typically run special software that checks everything against the standards and creates comprehensive reports showing exactly what needs fixing. This approach not only keeps operations running smoothly but also protects businesses from unexpected costs related to regulatory violations.

Types of Harmonic Mitigation Filters and Their Applications

Passive filters: Cost-effective solutions for fixed-frequency issues

Passive harmonic filters work based on pretty straightforward principles. They basically use inductors, capacitors, and occasionally resistors to go after those pesky distortion frequencies that mess up electrical systems. These kinds of filters tend to perform best in situations where the load stays relatively constant and predictable, since they're designed for those fixed frequency distortions we see so often in industrial settings. A big plus point for passive filters? Their price tag. For many manufacturers dealing with tight budgets, this makes them a no brainer option despite some limitations compared to active alternatives. Manufacturing plants across various sectors have seen real results from installing these filters. Take steel mills for example - after implementation,不少 facilities reported not only better energy efficiency but also extended lifespan of their expensive machinery. The savings add up over time, which explains why so many factories continue to rely on passive filtering solutions even as newer technologies emerge.

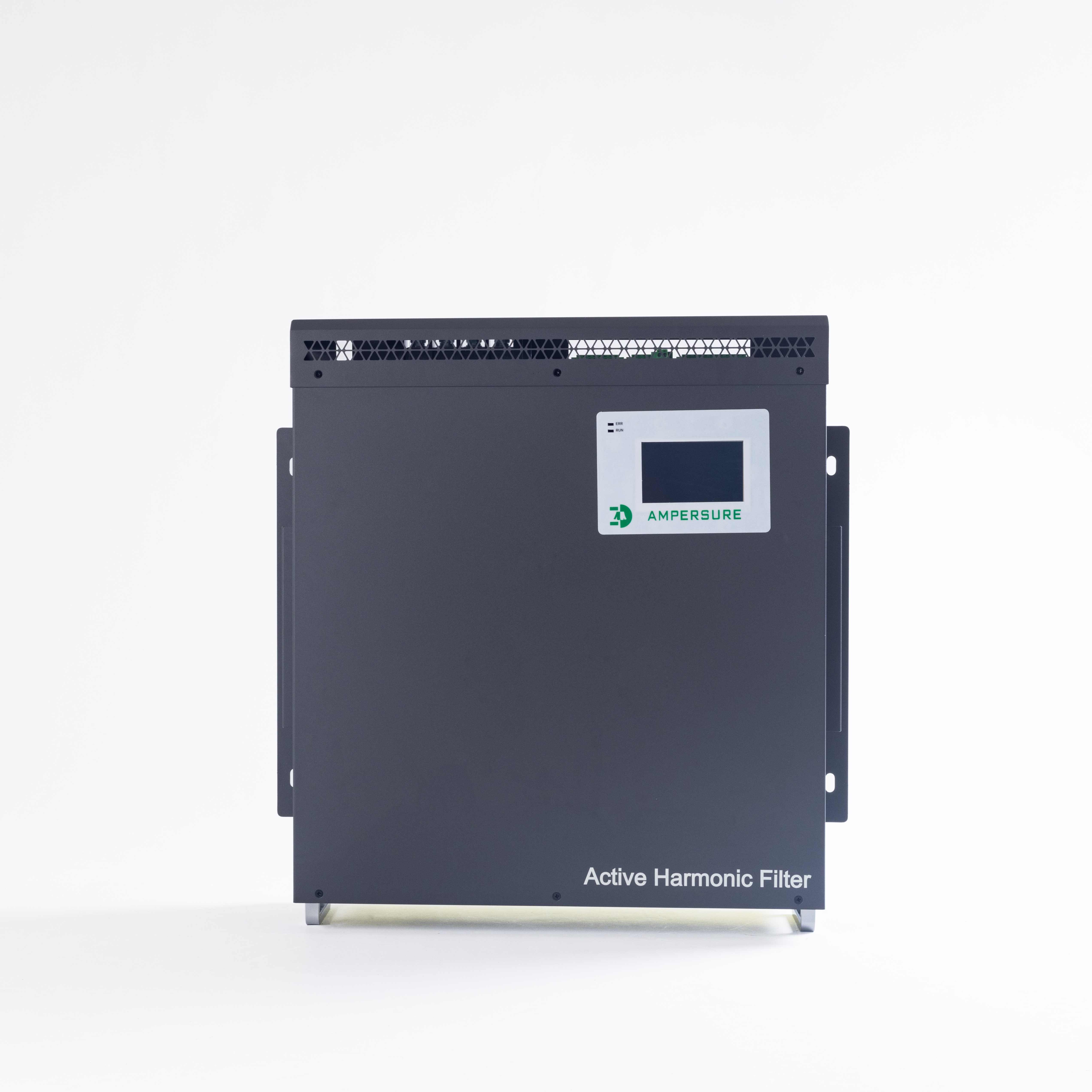

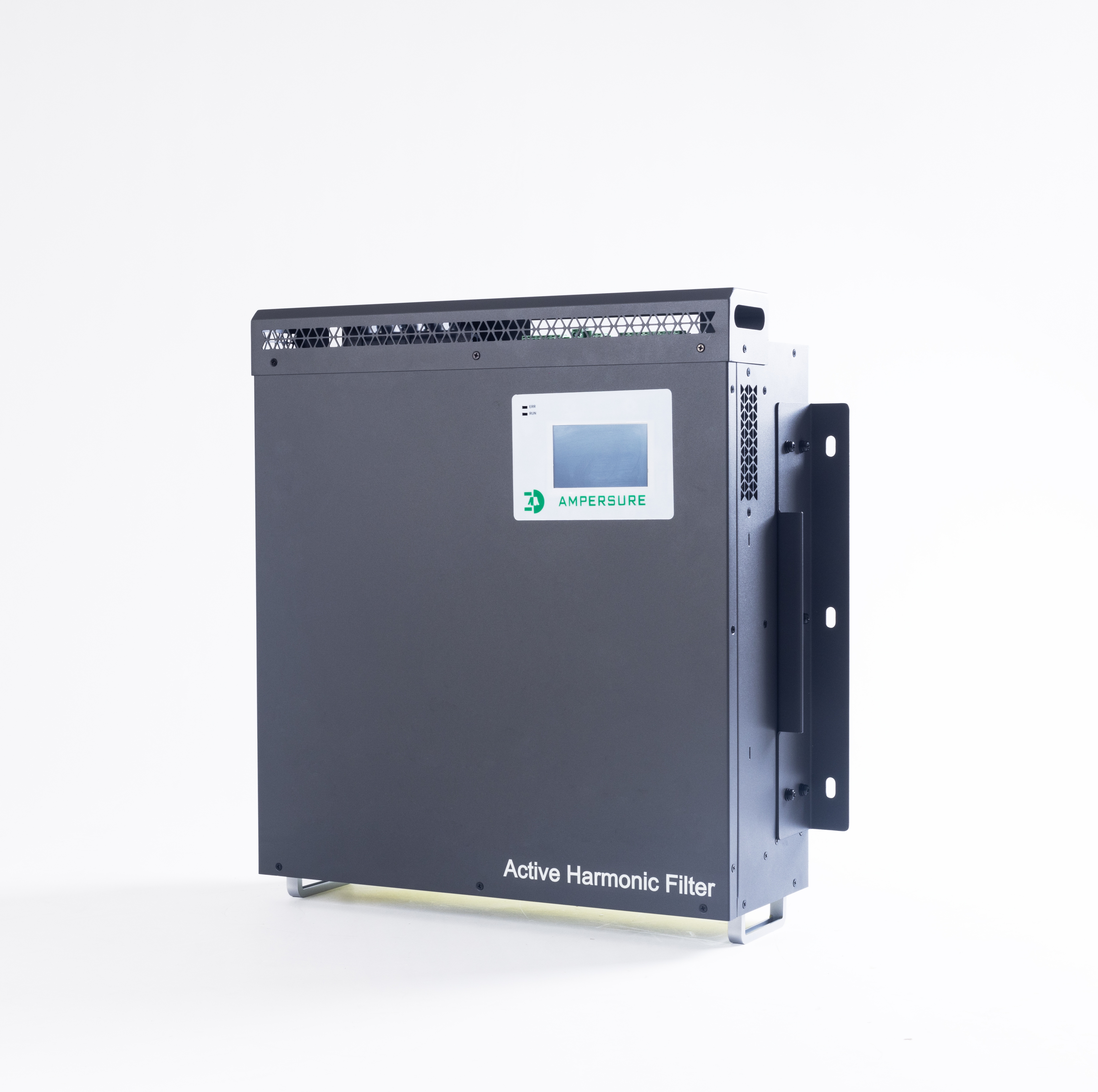

Active filters: Dynamic compensation for variable loads

Active filters work by compensating for those pesky harmonic distortions as they happen, adjusting on the fly when loads change and cutting down on harmonic issues before they get out of hand. Passive filters tend to work better when things stay pretty much the same, while active ones really shine where operations fluctuate constantly. Think about places like office towers or server farms where power needs jump around all day long. Today's active filter tech comes with smarter circuits that let them adjust in real time, making them stand out in tricky situations. What makes these filters special is how easy they fit into current electrical setups without major rewiring, which means better power quality overall. Beyond just reacting fast, these systems actually last longer and save money in the long run too. We've seen installations where companies avoided costly downtime and equipment failures simply by installing active filters instead of dealing with harmonic problems later.

Hybrid configurations combining PFC equipment advantages

Hybrid filter systems combine the best parts of passive and active filtering technologies to tackle harmonic issues in electrical systems. What makes them stand out is their ability to work efficiently across different frequencies, cutting down on harmonics while also boosting power factor at the same time. Many manufacturing plants and industrial facilities have seen real results after installing these hybrid setups, with noticeable drops in harmonic distortion levels and better power factor readings. When putting together a hybrid solution, engineers need to think through several important aspects first. The system needs to play nicely with whatever existing infrastructure is already in place, plus there's the matter of incorporating proper power factor correction devices into the mix. For facilities dealing with complicated electrical demands where both harmonic control and good power factor maintenance matter, these hybrid approaches often prove to be the most practical solution available.

Key Technical Specifications for Filter Selection

Voltage Rating and Current Capacity Requirements

Figuring out the right voltage and current ratings for harmonic filters requires looking closely at what the application actually needs plus understanding all those system parameters. First things first though, accurate calculations must be made based on the highest possible load conditions along with how the system voltage behaves under different circumstances. Getting these ratings to match up properly with the main electrical system isn't just good practice it's absolutely necessary if we want to avoid equipment failures down the road. When filters end up being too small or simply don't fit well with the existing setup, problems like overheating become inevitable and operations run inefficiently. Real world examples show exactly what happens when ratings fall short: factories experience more frequent breakdowns, maintenance crews get called out constantly, and overall costs go through the roof. These experiences highlight why getting specifications right matters so much in practical applications.

Frequency Range Coverage for Dominant Harmonics

When choosing filters, coverage over common harmonics should come first, especially those pesky 5th, 7th, and 11th order frequencies that pop up all over industrial settings. Getting these right means tackling harmonic distortion head on something that really matters because distorted power can mess up equipment and create all sorts of quality problems. To pick the right filter, look at how well it performs across various frequency ranges. Check things like THD reduction numbers and whether it handles changing loads without breaking down. Good coverage across the frequency spectrum makes a big difference for power factor correction gear too, which ultimately leads to systems running smoother day after day without unexpected hiccups.

Impedance Matching with Power Factor Improvement Devices

Getting the impedance right is really important when it comes to making harmonic filters work well with other power factor correction equipment already in place. When the impedance levels match properly, the different components actually start working better together, which means less harmonic distortion and improved overall power quality. There are several ways engineers check and adjust impedance settings these days. Most commonly they use specialized instruments called impedance analyzers or run simulations on computer software to find what works best. Take industrial facilities for example many run into problems where mismatched impedances cause unnecessary energy waste and reduced efficiency. These issues can usually be fixed by carefully matching up the impedance values so that all the harmonic filtering devices fit nicely within the electrical system's parameters without causing any conflicts down the line.

Temperature Tolerance in Operational Environments

When picking harmonic filters for industrial use, temperature tolerance should be at the top of the list, particularly where things get really hot out there on factory floors. These filters need to handle serious heat if they're going to last and work properly over time. Look at certifications from standards like IEC 61000 or IEEE 519 as a good indicator of how well a filter will hold up under pressure in these tough conditions. Industry professionals have seen plenty of cases where filters without proper temperature ratings start failing faster than expected because the heat just eats away at them. That's why smart engineers always check temperature specs first when spec'ing filters for plants, warehouses, or anywhere else where temperatures fluctuate wildly day to day.

Integration with Power Factor Correction Systems

Coordinating Harmonic Filters with PFC Equipment

Getting harmonic filters to work properly with power factor correction (PFC) systems makes all the difference in electrical installations. When these components interact well together, they boost both energy efficiency and system reliability across the board. The real trick comes down to setting up those harmonic filters so they play nice with whatever PFC systems are already in place. Many technicians run into trouble when things aren't configured right - think wrong settings or components not lining up correctly - and this often leads to wasted energy or even equipment breakdowns. Take some manufacturing plants as examples. After installing integrated systems that balance harmonic filtering with proper power factor correction, several facilities reported cutting their monthly electricity bills by around 15-20%. That kind of saving adds up fast over time.

Avoiding Resonance Issues in Combined Solutions

Combining harmonic filters with power factor correction gear requires special attention to resonance problems if we want these systems to work properly over time. Resonance basically happens when a system's own natural frequency lines up with outside forces, which can cause all sorts of trouble from reduced efficiency right through to actual physical damage. Good engineers know this upfront and incorporate various methods to check for and handle potential resonance issues right from the start of any installation project. Most professionals rely on computer modeling tools and simulation software to spot those tricky frequency mismatches before they become real problems in systems where everything wasn't thought through properly. Experience shows us that many electrical systems end up suffering serious frequency related problems precisely because nobody bothered to look at resonance factors during initial planning stages, so it really pays off to spend extra time evaluating these aspects during the design process.

Optimizing System Efficiency Through Parallel Compensation

When it comes to parallel compensation, we're talking about harmonic filters paired with power factor correction devices working hand in hand to boost how well the whole system runs. What makes this approach so effective is that it tackles both harmonic issues and improves power factors at the same time, creating a much cleaner electrical environment. Industries that deal with constantly changing power needs tend to get the most out of these combined systems since single solution approaches just don't cut it anymore. Money wise, companies see real savings too. Research indicates that facilities using this dual approach typically save more on energy bills compared to places sticking with individual fixes. Better efficiency means lower day to day expenses while also making sure the power quality stays consistent over time, which matters a lot for manufacturing operations where downtime can be costly.

Cost-Benefit Analysis and ROI Considerations

Evaluating Initial Investment vs Long-Term Energy Savings

Looking at harmonic filters requires balancing what something costs upfront versus how much money it might save on energy bills down the road. Installation costs plus ongoing maintenance vary quite a bit depending on whether we're talking about passive filters, active ones, or those hybrid models that combine both approaches. Smart companies actually do some math here too looking at what they could save in the long run, and often find those savings make up for most if not all of what they spent initially. For instance, many manufacturers report cutting their monthly electricity bills by around 15% after installing proper harmonic filtering systems. The numbers really tell the story best though. Most experienced engineers recommend creating simple charts showing where the break even point lies between what was invested and when actual savings start happening month by month.

Calculating Lifecycle Costs of Different Filter Types

Looking at the full cost picture over time gives companies a better sense of what different filter options really cost in the long run. We're talking about everything from buying the filters initially, installing them, keeping them running smoothly, all the way to getting rid of them eventually. When comparing passive, active, and hybrid filters side by side, businesses get clearer insights into what works best for their particular situation. Take passive harmonic filters for example they tend to be cheaper upfront and need less ongoing attention compared to active ones that demand constant checkups and adjustments. Real world case studies often show how failing to consider these lifetime costs leads to unexpected expenses down the road. Many companies have learned the hard way that picking the wrong filter type creates operational headaches and wasted money, something every business should keep in mind when budgeting for equipment purchases.

Factoring in Maintenance Requirements for Active Components

Harmonic filters of the active type need much more hands-on maintenance compared to passive ones, which really impacts how much they cost to own over time and how well they perform. Anyone looking at the bottom line for active components needs to factor this into their planning from day one. Plants running on active filters would do well to set up regular maintenance schedules before problems strike. We've seen too many cases where neglect leads to expensive shutdowns or repair bills. Take Facility X for instance they ignored maintenance until their system failed completely during peak production hours. Regular servicing keeps those filters working at their best while avoiding the headache of sudden breakdowns. And let's face it proper maintenance isn't just about preventing disasters it actually helps save money in the long run through better energy efficiency.

Hot News

Hot News